Get Your HVAC System Ready for Inspection: A Homeowner's Guide

A thorough HVAC inspection can uncover hidden problems and significantly boost your system’s energy efficiency. This guide will walk you through what an HVAC inspection involves, essential steps to take beforehand, a homeowner’s checklist, common reasons for inspection failures and how to avoid them, ideal scheduling for inspections, and how Home Energy Group, Inc.’s 25 years of local experience and 15% maintenance plan discount can help you get ready. Each section builds on the last, providing a clear path to a safe, compliant, and cost-effective HVAC assessment.

What Exactly Is an HVAC Inspection, and Why Does Preparation Matter?

A professional HVAC inspection is a detailed review of your heating, ventilation, and air conditioning system’s condition, safety, and efficiency. By checking airflow, refrigerant levels, electrical connections, and component integrity, an inspection ensures your system runs reliably, improves your home’s air quality, and meets local regulations. Being well-prepared not only makes the inspector’s job easier but also helps catch minor issues before they turn into expensive repairs.

What Does a Professional HVAC Inspection Cover?

A professional inspection typically includes checking refrigerant pressure, electrical safety, coil condition, ductwork integrity, condensate drain function, and thermostat accuracy.

- Refrigerant Level Check – Confirms the system has the correct amount of refrigerant for optimal cooling.

- Electrical Connection Test – Ensures safe voltage and amperage levels.

- Coil and Filter Inspection – Looks for dirt buildup that can hinder heat transfer.

These checks verify that your system is performing as it should, setting the stage for better energy use and improved safety.

How Does Getting Ready Improve Your HVAC Inspection Results?

Preparing by clearing access, changing filters, and noting any unusual issues makes the inspection more accurate and efficient. When the areas around your indoor and outdoor units are clear, the technician can work quickly and thoroughly. Documenting any strange noises or leaks helps the technician focus their diagnostic efforts, reducing downtime and the risk of missed problems.

What Are the Advantages of a Successful HVAC Inspection?

- Better Energy Efficiency – Optimized airflow and proper refrigerant levels can lead to lower energy bills.

- Improved Indoor Air Quality – Clean filters and ducts help reduce allergens and pollutants.

- Longer Equipment Life – Catching wear and tear early can prevent components from failing prematurely.

These benefits work together to ensure your home stays comfortable, healthy, and saves you money in the long run.

What Should You Do Before Your HVAC Inspection? Key Preparation Tips

How to Ensure Clear Access to Your Indoor and Outdoor HVAC Units

Move any furniture, stored items, or plants away from your units to give the inspector unobstructed access. Maintain a clear space of about two meters around outdoor condensers to prevent debris from interfering with coil and fan inspections. Indoors, ensure at least half a meter of clearance around furnaces and air handlers for safety and a thorough examination.

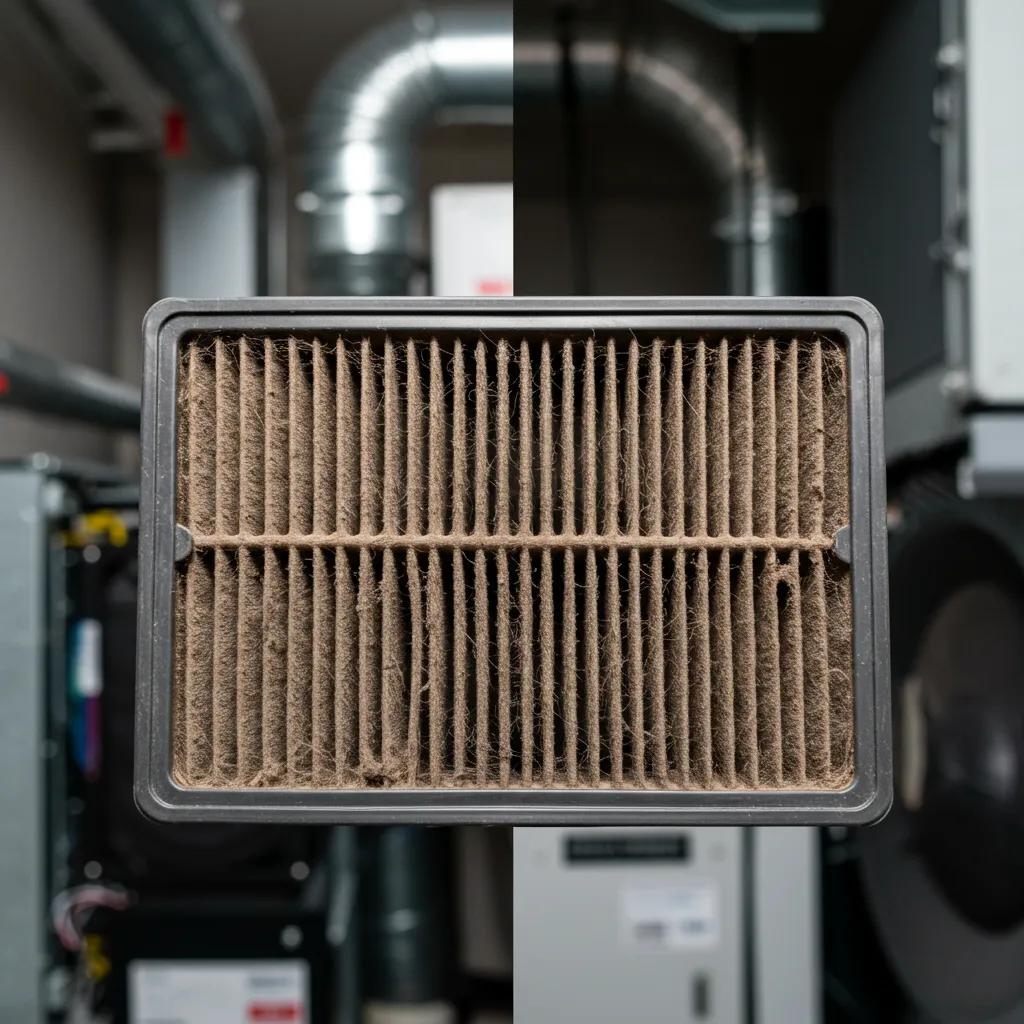

Why Changing Your Air Filter Before an Inspection is Important

A clean air filter is crucial for regulating airflow, preventing coils from freezing up, and reducing the workload on your blower motor. Swapping out a dirty filter for a new one restores proper air exchange and ensures that efficiency readings during the inspection accurately reflect your system’s performance. Clean filters also prevent dust buildup inside your system, which can help avoid inspection failures.

How to Check and Adjust Your Thermostat for Inspection Readiness

Make sure your thermostat is showing the correct temperature and that its batteries are fresh. Set the system to both heating and cooling modes to confirm it responds properly. Accurate thermostat calibration allows the inspector to precisely evaluate its control accuracy and your home’s comfort consistency during performance tests.

What to Look For: Noting Strange Noises, Smells, and Visible Problems

Listen for any unusual sounds like grinding, rattling, or clicking. Pay attention to any musty or burning smells, which could indicate airflow issues or electrical problems. Visually inspect visible duct seams for gaps and check for any oil or refrigerant stains around the outdoor lines. Jotting down these observations will help the technician pinpoint potential issues more quickly.

How to Clear Vents, Registers, and Surrounding Areas

Vacuum any dust or pet hair from your supply and return registers to maximize airflow and speed up the inspection process. If you notice oily residue, remove and wash the vent covers. Keep at least 30 centimeters of clear space around each register to allow for accurate airflow and temperature measurements.

What's Included in a Home HVAC Inspection Checklist?

Which HVAC Components Are Typically Inspected?

Most inspections focus on the main parts that affect performance and safety.

| Component | Function | Inspection Focus |

|---|---|---|

| Air Filter | Regulates airflow | Cleanliness and proper fit |

| Thermostat | Controls temperature | Calibration and responsiveness |

| Condenser Coil | Facilitates refrigerant heat exchange | Dirt buildup and physical damage |

| Electrical Wiring | Delivers power | Integrity of connections |

How to Use a Localized HVAC Inspection Checklist for Southwest Washington Homes

Southwest Washington’s humid climate can increase the risk of coil corrosion and encourage moss growth around outdoor units. Make sure to follow local permit requirements by confirming that any replacement projects have the necessary municipal approval. Tailor your checklist to regional standards by ensuring condensate lines are properly sloped to prevent freezing in winter.

What Seasonal HVAC Preparation Should You Include?

Getting your system ready for each season helps prevent performance issues and inspection failures:

- Spring – Clean coils, test cooling capabilities, and check for duct leaks.

- Autumn – Clear out condensate lines, inspect the heat exchanger, and test safety controls.

Adjusting your maintenance tasks for each season keeps your system running reliably and improves inspection outcomes.

How to Document and Report Issues Before the Inspection

Keep a simple record of dates, what you observed, and any photos of leaks, corrosion, or loose parts. Use a spreadsheet or notebook to note down component serial numbers and the dates of your last service. Providing this information to your inspector can speed up the diagnostic process and confirm your maintenance history.

What Are Common HVAC Inspection Failures and How Can You Avoid Them?

How Do Dirty Air Filters Impact Your HVAC Inspection?

Clogged air filters restrict airflow, forcing your blower motor to work harder and potentially causing the system to shut down. This reduced airflow also lowers heat transfer efficiency and can lead to coils freezing up when the air conditioner is running. Replacing filters monthly, or as recommended by the manufacturer, keeps airflow optimal and prevents this common failure point.

What Are the Signs of Refrigerant Leaks and Their Consequences?

Signs of refrigerant leaks include frost on the refrigerant lines, hissing sounds, or a noticeable decrease in cooling performance. Low refrigerant levels can cause the compressor to overheat and significantly increase energy usage. Detecting leaks early through visual checks and pressure tests helps prevent performance loss and costly compressor damage.

Why is Faulty Wiring a Critical Concern During Inspection?

Loose or corroded electrical connections can overheat, creating a fire risk and causing intermittent system shutdowns. Inspectors will check the wiring in your breaker panel, the integrity of your control board, and safety switch connections. Ensuring all electrical contacts are secure and free of corrosion is essential to avoid serious safety violations.

How Can Cracked Heat Exchangers Affect Your Home's Safety?

A cracked heat exchanger in your furnace can allow carbon monoxide to mix with the air distributed throughout your home, posing a serious health risk. Inspectors use specialized tools and visual checks to find cracks or corrosion. Scheduling annual inspections and addressing any issues promptly eliminates this significant safety hazard.

How Often Should You Schedule HVAC Inspections and Maintenance?

What Is the Recommended Inspection Schedule for Residential HVAC Systems?

It’s a good idea to schedule a comprehensive inspection at least once a year, alternating between spring (for cooling systems) and fall (for heating systems). This timing aligns with seasonal changes in demand and ensures each mode is checked before its peak usage period, maximizing comfort and reliability.

How Does Regular Maintenance Extend Your HVAC System's Lifespan?

Routine maintenance involves cleaning coils, lubricating moving parts, and verifying that controls are operating safely. By reducing wear and tear on components like compressors and motors, regular servicing can add up to five years to your HVAC system’s lifespan. Consistent care also helps maintain manufacturer warranties and prevents premature part failures.

What Are the Benefits of a Maintenance Plan with Professional HVAC Services?

Home Energy Group, Inc.’s maintenance plan includes two inspections per year, priority scheduling, and a 15% discount on services and parts. This plan helps ensure ideal home comfort, reduces repair expenses, and provides peace of mind through expert system tuning and seasonal adjustments.

How Can Home Energy Group, Inc. Help You Prepare for Your HVAC Inspection?

What Expertise Does Home Energy Group Bring to HVAC Inspections in Southwest Washington?

With a specialization in new construction, remodels, and system replacements, Home Energy Group’s technicians are well-versed in local building codes and climate-related wear factors. Their extensive regional knowledge ensures that permit inspections are handled correctly and that seasonal maintenance addresses common humidity issues found in coastal and inland areas.

How Does a Maintenance Plan with Home Energy Group Save You Money?

A customized maintenance plan with Home Energy Group offers a 15% discount on all service calls and replacement parts, helping homeowners lower their long-term repair costs. By combining scheduled inspections with proactive tune-ups, customers can maximize energy efficiency and avoid expensive emergency repairs.

How to Schedule Your Professional HVAC Inspection with Home Energy Group

Contact Home Energy Group, Inc. through their website’s contact form or by phone to arrange a convenient inspection appointment. Their efficient scheduling and local presence ensure timely service with minimal disruption to your daily life.

Frequently Asked Questions About Preparing for Your HVAC Inspection

Instead of a traditional Q&A format, this section addresses common homeowner questions through concise topic summaries to guide your preparation.

What Are the Key Steps to Prepare for an HVAC Inspection?

The essential preparation steps include clearing access to all units, replacing air filters, documenting any noises or leaks, testing thermostat response, and cleaning vents. Completing these tasks ensures a thorough inspection and an accurate assessment of your system’s performance.

How Long Does an HVAC Inspection Typically Take?

A standard residential HVAC inspection usually takes between 60 and 90 minutes, depending on the system’s complexity and how well-prepared the homeowner has made it. Inspections in well-prepared homes often conclude closer to the 60-minute mark.

What Happens If My HVAC System Fails Inspection?

If your system doesn’t pass, the inspector will outline the necessary repairs or adjustments. You can then schedule follow-up service—taking advantage of any maintenance plan discounts—to address the issues. A subsequent re-inspection will confirm that the system is compliant and operating safely. HVAC maintenance program is essential for keeping systems in check.

Are There Permit Requirements for HVAC Inspections in Washington State?

Washington State may require permit inspections for new installations, major system replacements, or significant modifications to ductwork. It’s important to check local building codes and confirm that any recent system replacements were properly permitted to avoid inspection delays.

How Can I Improve My Home's Energy Efficiency Before an Inspection?

Before your inspection, consider sealing duct joints, insulating accessible ductwork, installing a programmable thermostat, and adding weatherstripping to doors and windows. These actions help reduce energy loss and allow your system to demonstrate its peak efficiency during performance tests.

A successful HVAC inspection starts with careful preparation, clear documentation, and expert assistance. By following this guide and partnering with Home Energy Group, Inc., you can ensure a thorough, efficient, and cost-effective assessment that protects your comfort, safety, and savings in your Southwest Washington home.

Conclusion

Preparing your HVAC system for inspection not only enhances its efficiency but also ensures a safer and more comfortable home environment. By following the outlined steps and leveraging the expertise of Home Energy Group, Inc., you can avoid common pitfalls and maximize your system’s performance. Don’t wait for issues to arise; take proactive measures today to secure your HVAC system’s reliability. Contact us now to schedule your professional inspection and enjoy peace of mind knowing your home is in expert hands.